Full-Automatic Vickers Hardness Tester

An Official distributor of Future-Tech in Viet Nam

FULL-AUTOMATIC VICKERS HARDNESS TESTER FV-ARS 9000

Full-Automatic Vickers Hardness Tester FV-ARS 9000 is a more innovated Vickers hardness testing system

Features of Full-automatic Vickers hardness Tester

FV-ARS 9000 is a Full-automatic Vickers Hardness Testing Machine manufactured by Future-Tech – Made in Japan

Sampleʼs Tilted Surface Tracing Function

- Easy setting of tilt angle enables to control Z-axis along the sampleʼs tilted surface.

- This function enhances “Load applying accuracy”, shortens “Auto-focus time” and protects a sample and lens/indenter from a collision.

Measured Image Saving Function

- You can check the images of all the measured indents.

- By re-measuring the indent’s images, you can modify data easily.

Various Measurement Patterns

A series of measurement operations: Continuous Indentation – Focusing – Reading – Data Record: Just by selecting a measurement pattern, all testing will be

full-automatic with high speed.

- Most Advanced System with High-speed Sample Profile Memory Function.

- High-speed, High-accuracy, High-repeatability, Easy-operation, Improved Read Power.

- More Reliable for Large quantities of testing without human error.

Data Processing Software

The capability of Reading unclear indents on an un-mirror surface has been improved by more advanced Data Processing Software.

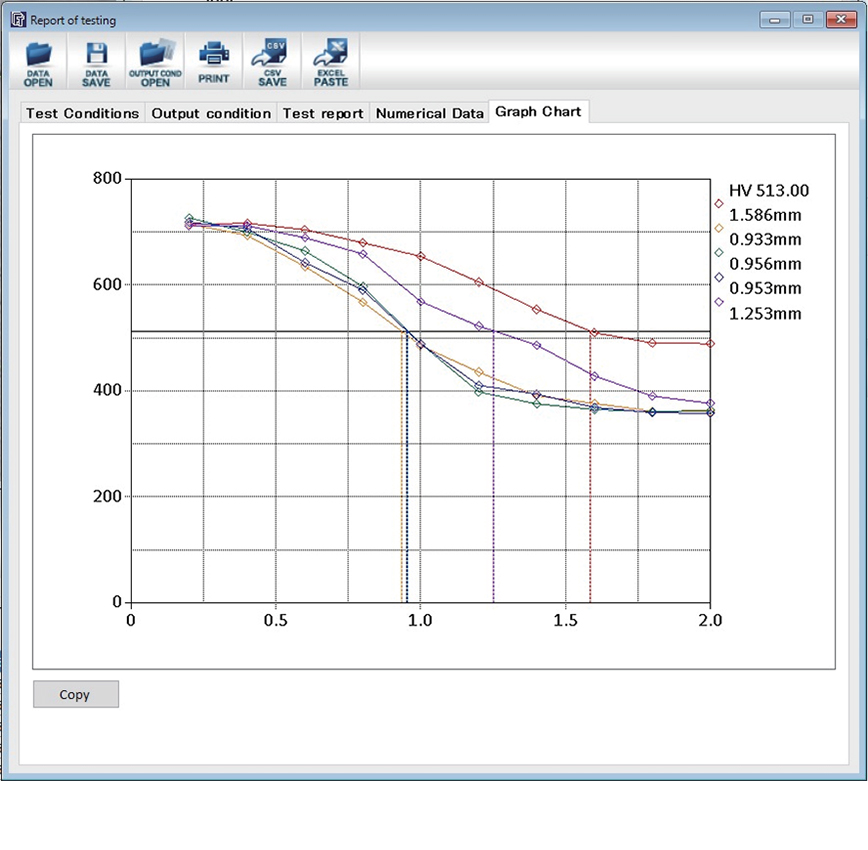

Various Data Output Format and Statistical Processing

- Case Depth of indicated HV Hardness can be displayed instantaneously on the Chart after continuous Measurements on Carbonized Layer.

- Various Data Output available – Measurement Data, Hardness Distribution Chart, Case Depth, Max. Value, Min. Value, Mean Value, Dispersion, Standard Deviation, Coefficient of Variation, OK-NG Criteria, Conversion Data, etc.

- Display and Output of Color Profile Picture linked with Hardness Values – Standard Function.

Specifications of the Full-Automatic Vickers Hardness Tester

STANDARD SYSTEM COMPONENTS

Analog Vickers Hardness Tester Model: FV-110S (OPTION: FV-310S, FV-810S available)

Automatic X-Y Stage & Motor Drive Unit

CCD Camera

Complete set of PC: 23” Wide LC Monitor, Mouse, Keyboard, and Joy-Stick with Controller

Standard Software FT-ZERO for System

HARDNESS TESTER

Model

Model FM-110S: Stage Elevation Motor Built-in

Type

Analog Type: Controllable Loading Operation by External PC

Test Load

Type A:

N : 9.807 19.61 29.42 49.03 98.07 196.1 294.2 490.3

kgf: 1 2 3 5 10 20 30 50

Type B:

N: 2.942 4.903 9.807 29.42 49.03 98.07 196.1 294.2

kgf: 0.3 0.5 1 3 5 10 20 30

Loading Mechanism

Automatic Load / Hold / Release Method

Focus Operation

Automatic / Manual Operation available (Manual operation is driven by a motor)

Auto-Stage Elevation

Automatic: by Built-in Stepping Motor / Manual: by Joy-Stick Operation

*Safety Devices equipped for Overrun of Elevation

Precision Vise

Standard: Max. Opening: 50mm

Rotation Turret

Automatic / Manual changeable

Loading Speed

First speed:120μm/sec & Real load speed:60μm/sec

Dwell Time

5 – 40 sec

Object Lens

Type A: X10 / Type B: X10 & X20 (Optical Parts for 3rd Lens Built-in)

Measurement Scale

Vickers Hardness (HV) / Knoop Hardness (HK) is optional

AUTOMATIC X-Y STAGE

Driving Motor

Stepping Motor

Driver Control

By icon: 2 Steps Speed available in X-Y-Z axis

By Joy-Stick : Flexible Speed Changing in X-Y-Z axis

Dimension

110×110mm

Max. Movement

50×50mm

Min. Movement

1μm

Moving Speed

1 – 25 mm / sec adjustable

Movement Program Pattern

Straight Line (Vertical & Horizontal) / Zigzag / Circle / Arc / Line Set for any Angle (8 Lines and Max. 998 indents on 1 Line/Total 49950 indents are measurable.) / Specificity of 2 Points / Specificity of Angle / Sample Profile Memory Function & Measurement along with Profile Line

AUTOMATIC READING

Pattern Setting

Start Position Setting for Straight Line and Position Setting for Random / Teaching Mode shall be performed by Mouse-Click.

Measurement Repeatability

±0.8% on Test Block 800 HV / 10 kgf

Auto-Focus Time

Shortest 3 sec

Auto Reading Time

Approx. 0.2 sec / 1 indent

Measurable Min. Indent

10 μm

Min. Measurement Unit

0.1 μm